Talk to an ergo expert: (888) 420-3200 or Email Us

SECURE POLES

Several SERIES-118 articulating mounts feature a central mounting pole. Examples include the LS413, LS413D, LS9137S, LS9137D, LS1512D, LS1512Q and the TRS413. The pole is offered in two standard lengths of 14” and 28” and is designed to work with all compatible SERIES-118 Mounting Kits.In Roller Track applications with a vertical mounting surface, this pole is installed on MKIT-M2 and MKIT-N2 (or their first-generation counterparts MKIT-M and MKIT-N). Unlike several other mounting kits which are closed at the bottom (e.g. MKIT-C or MKIT-D), these Roller Track mounts feature a through hole, allowing the pole to be secured at any height. The VESA compatible articulating brackets can then be positioned above and/or below the rail, thus addressing a large number of mounting scenarios. Here are some examples:

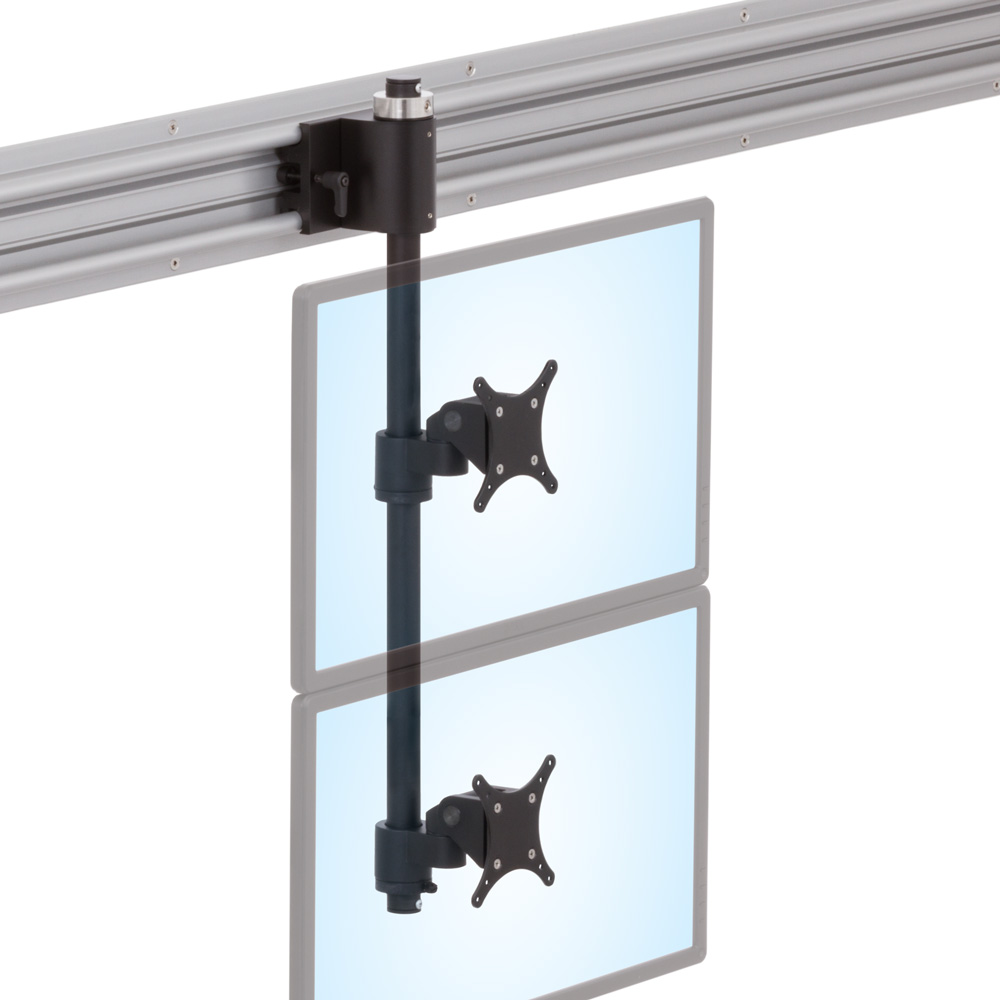

LS413D with a “drop-down” configuration on an MKIT-N2, and the two mounting brackets installed below the rail

LS413D with a “drop-down” configuration on an MKIT-N2, and the two mounting brackets installed below the rail

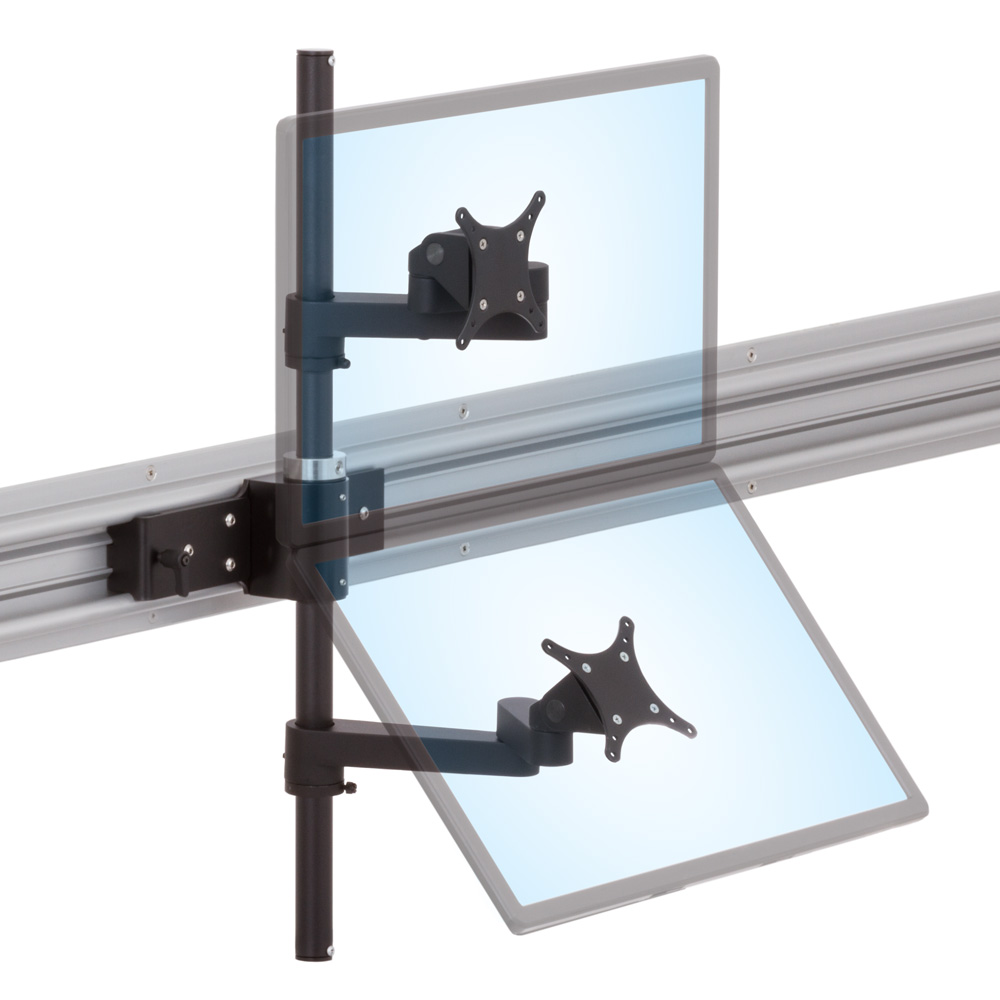

LS9137D with the pole centered on an MKIT-N2 and the two articulating arms positioned above and below the rail

LS9137D with the pole centered on an MKIT-N2 and the two articulating arms positioned above and below the rail

These Roller Track applications require the use of a Secure Mounting Pole (P118RS), which differ from the standard pole as they feature two security screws and a shaft collar.

The security screws are located near the top and bottom of the pole and are there to simply ensure that the pole and its payload do not drop through or pull out of the trolley mount. This can be especially beneficial during installation or adjustment of the mount.

The shaft collar is installed just above the mounting kit with its set screw tightened against the pole. The position of the shaft collar with respect to the pole thus establishes the relative height of the pole with respect to the rail. The two set screws of the mounting kit itself are used to adjust the rotational resistance of the pole within the mounting kit as desired.